4 TRENDS YOU SHOULD NOT MISS IN NVH ENGINEERING [PART 2]

Trend 3 – Lightweight Material Design Impacting NVH

The third trend that Steven Dom discusses is the one that most affects driving behavior, traffic handling, or durability: weight reduction. NVH engineering is no exception to this rule.

Less Weight Means Less Vibration

Like the most famous models on the catwalk, automotive engineers fear adding a few pounds to their latest design. Indeed, weight is the enemy because it increases fuel consumption in conventional cars and reduces the range of electric vehicles.

But then, mass becomes the friend of the NVH engineer. It blocks noise and reduces vibration. Previously, NVH engineers could simply add noise and vibration damping materials to mitigate part vibrations—but now, that may not be necessary.

Dom says: “Interestingly, the pursuit of lighter materials and detailed design is not necessarily bad news for NVH engineers. It encourages creativity and innovation in material design.”

Lightweight Materials Are Key

Lightweight materials are at the core of R&D activities for many Tier 1 and Tier 2 suppliers. For example, 3M China invests heavily in R&D to develop advanced automotive materials. The company aims to provide the automotive industry with materials that improve fuel efficiency while enhancing safety and vehicle performance.

To better assess acoustic material properties, 3M China established its own R&D center in Shanghai. This internal testing facility significantly reduces test time and helps 3M develop new skills and capabilities.

“Simcenter testing products and services help us find solutions to achieve a great balance between cost-effectiveness, weight, and vehicle performance.”

-Wan Quan, Product Engineer, Acoustic Materials Team, Automotive Division, 3M China-

For more details on 3M China’s results, see the success story: “3M China Chooses Simcenter Testing Solutions to Help Automakers Reduce Interior Noise.”

Metamaterials Drive Innovation in Acoustic Material Design

How can lightweight materials become an ally for acoustic engineers? In fact, composites and metamaterials offer many opportunities for innovation. But what are metamaterials?

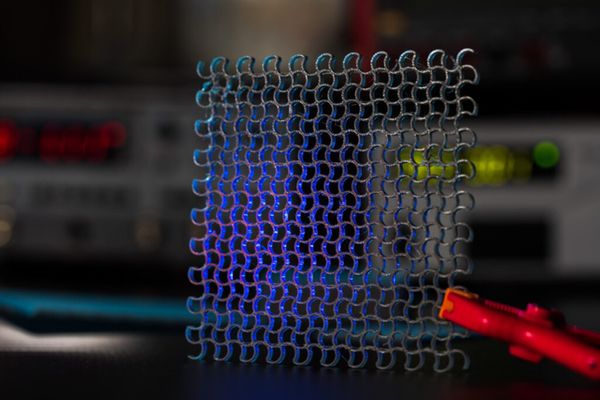

They refer to any materials specifically designed to have properties that natural materials do not possess. Metamaterials are usually assemblies of multiple elements, made from metals and plastics. The components are often arranged in repeating patterns at scales smaller than the wavelength of the phenomenon they affect. Metamaterials have numerous uses, including diffracting light, absorbing, or refracting certain wavelengths. They have applications in optics, thermal management, and acoustics.

Metamaterial sample developed in a laboratory

So how does metamaterial development support NVH engineering? KU Leuven, near one of our Siemens offices in Belgium, published research results on their website. These findings provide deep insight into the acoustic potential of metamaterials.

Of course, the automotive industry is applying these innovations. Recently, Nissan introduced a concept using acoustic metamaterials. The Nissan Ariya Concept features new material design. These soundproofing materials significantly reduce road noise and improve driving comfort. They weigh only a quarter of conventional acoustic materials (like rubber mats).

However, they provide equivalent road noise reduction performance. All this comes with the added benefits of reduced vehicle weight, improved driving performance, and fuel efficiency.

Watch the Nissan Ariya Concept in the video below:

“The pursuit of lighter materials drives creativity and innovation in material design.”

Trend 4 – Automation Changes How We Perceive NVH

The fourth trend is inevitable given global population growth. Urbanization is a major trend of the 21st century. In densely populated areas, smart mobility has become essential.

Automated mobility solutions provide seamless, flexible, and multimodal daily travel. Almost all car manufacturers are participating in the race for partially or fully automated vehicles. For NVH engineers, is this trend exciting or worrisome?

New Noise Sources, New Concerns

With autonomous vehicles, NVH engineers will have to address new noise sources. No loud noise like an engine roar exists, but many small noises combine into a disturbing cacophony. Essentially, a fully autonomous car is equipped with sensors acting as the vehicle’s ears and eyes—and these sensors generate noise.

For optimal operation, sensors must not overheat and are cooled by fans or liquid. Hearing subtle “whooshing” or “rustling” sounds? As engine noise fades, we become more sensitive to auxiliary system noise.

Additionally, NVH engineers must consider vibration effects on sensors. Vibrations from tires on rough roads may affect radar functionality in bumpers. Similarly, high-fidelity cameras may react to constant vibrations.

Indeed, the future brings many challenges for NVH engineers as vehicles evolve toward higher automation.

Self-Driving Taxi or Roller Coaster?

Riding a roller coaster can be thrilling, but sitting in a self-driving taxi should be smooth and comfortable.

The biggest challenge is predicting consumer expectations and reactions to fully autonomous cars. How will people feel inside a self-driving vehicle? It’s a puzzling question.

When drivers become passengers, they might expect an exciting ride. But what feels comfortable? The first barrier is anxiety from lack of control. If a cyclist suddenly cuts in front of your car, can you react immediately? Steering jolt, tire squeal, seat tilt—all sensations affect comfort perception.

What if you are inattentive and the car makes sudden adjustments? This could be very unsettling or even frightening.

Moreover, car sensors can detect traffic situations that human eyes cannot. Suppose there’s a vehicle cluster at the end of a traffic jam after a curve—you might not notice it, but the car detects the congestion and slows down unexpectedly while you’re relaxed on the highway. Not the most pleasant feeling, right?

New Direction for Comfort

Above all, NVH engineers have a new task: eliminating surprising noise and vibration that cause fear. How? This is under debate, as fully autonomous cars are not yet common. Engineers consider various options: optical, auditory, or haptic feedback to inform passengers “what is happening.”

In any case, some form of feedback is desired. It can reduce kinetosis or motion sickness and increase overall comfort perception. Once NVH engineers master all parameters, they face the ultimate challenge: designing a comfortable in-car audio system.

In a previous discussion, Steven Dom emphasized the role of active speaker design in creating a pleasant sound atmosphere. He also highlighted the difficulty: individuals differ, so how can engineers design a speaker system appealing across age, gender, origin, social, and cultural backgrounds affecting comfort perception?

What’s Next for NVH Engineering?

In a prior discussion, Steven Dom highlighted the exciting challenges ahead for NVH engineers. As recent trends drive innovation, he is curious about what the future holds.

He mentioned: “One of our biggest challenges as NVH engineers is minimizing noise we can’t easily influence, such as road noise. We can use complex propagation analysis techniques to reduce it. But when I saw companies like Hyundai implement active road noise cancellation (RANC), I wondered: ‘What’s next?’”

Indeed, in late 2019, Hyundai Motors launched advanced active road noise control (RANC) technology, targeting variable road noise rather than relatively continuous engine noise.

Dom considered whether active wind noise cancellation could be the next innovation: “Clearly, automakers are interested in reducing the discomfort from wind noise. But unpredictable broadband noise is hard to counter. Who knows what we’ll achieve in the coming years?”

Source: Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was established in 2014. By 2018, we became a Smart Expert Partner—the leading partner of Siemens Digital Industries Software in Southeast Asia-Pacific for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

Enterprises and customers who wish to contact SDE TECH can use the following information:

Enterprises and customers who wish to contact SDE TECH can use the following information:

English

English Tiếng Việt

Tiếng Việt 한국어

한국어