In machining, MRR CNC (Material Removal Rate) is a critical indicator that reflects the amount of material removed per unit of time. Optimizing this metric helps significantly shorten production cycles while extending tool life. Today, VoluMill, provided by SDE Tech, is leading the trend thanks to its ability to maintain a constant cutting load throughout the machining process. In the following article, SDE Tech will provide you with the most detailed and in-depth technical insights into this solution.

1. What is MRR CNC?

To optimize any process, the first step is to clearly understand the metrics used to measure it. In metal cutting and machining, MRR CNC serves as the central benchmark for material removal capability.

1.1 Definition of MRR CNC

To answer the question “What is MRR CNC?”, it is important to note that MRR is the abbreviation for Material Removal Rate, also referred to as the material removal speed. From a technical perspective, this metric represents the volume of workpiece material removed within a specific unit of time. It is the most direct parameter for evaluating how efficiently a CNC machine operates, particularly during roughing and semi-finishing operations.

1.2 Units of Measurement and Physical Significance

Material Removal Rate is commonly expressed in cubic centimeters per minute (cm³/min) or cubic millimeters per second (mm³/s). A higher MRR indicates that the machine is removing material more rapidly, which can significantly reduce the machining cycle time. However, increasing MRR requires careful consideration of cutting tool strength, tool life, and the spindle power capacity of the CNC machine to ensure stable and reliable machining performance.

2. The Role of Material Removal Rate in Machining Performance

Why do engineers continuously seek ways to increase the Material Removal Rate (MRR)? The answer lies in achieving the optimal balance between productivity and business profitability.

2.1 Shortening Production Lead Time

By increasing the material removal rate, the actual cutting time of the tool on the workpiece is reduced. This enables manufacturers to accelerate delivery schedules, free up machines sooner for new orders, and thereby directly increase revenue using the same equipment infrastructure.

2.2 Optimizing Operating Costs

Every hour of machine operation incurs costs related to electricity consumption, coolant usage, labor, and machine depreciation. By improving machining efficiency through MRR optimization, the fixed cost per part is reduced, allowing manufacturers to sustainably improve profit margins.

2.3 Evaluating Cutting Tool Capability

A clear understanding of what MRR CNC is also helps engineers select the most appropriate cutting tools. Modern high-performance cutting tools are often designed to withstand extremely high MRRs. Using premium tools while operating at a low MRR represents a significant waste of resources and fails to fully leverage the tool’s designed performance.

3. Fundamental MRR Calculation Formulas for CNC Engineers

To apply MRR effectively in practice, engineers must rely on accurate, standardized calculation formulas rather than subjective estimation. Each machining operation has its own specific method for calculating MRR.

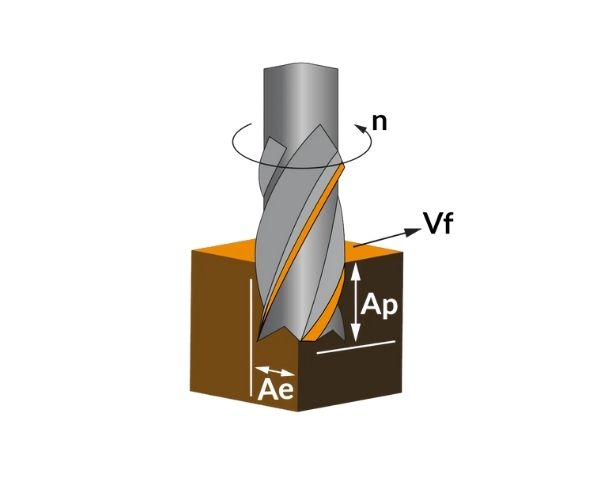

3.1 MRR Formula for Milling Operations

In CNC milling, the Material Removal Rate (MRR) is determined by the combination of axial depth of cut (ap), radial width of cut (ae), and feed rate (Vf).

The MRR formula for milling is defined as:

MRR = ap × ae × Vf

Where:

- ap (Axial Depth of Cut): Axial cutting depth along the tool axis (mm)

- ae (Radial Depth of Cut): Radial cutting width (mm)

- Vf (Feed Rate): Table feed rate (mm/min)

3.2 MRR Formula for Turning Operations

For turning processes, MRR calculation is based on cutting speed, feed per revolution, and depth of cut.

The formula is as follows:

MRR = v × f × d × 12

Accurate application of these formulas is the first step for CNC engineers to gain control over the machining process. However, to achieve true optimization—especially at high cutting loads and complex geometries—the use of advanced machining software becomes indispensable.

4. Physical Limitations When Increasing MRR CNC

Increasing MRR is not as simple as maximizing the parameters in the formula. In real-world manufacturing, physical constraints always exist, forcing engineers to find smarter ways to overcome them.

4.1 Spindle Power and Torque Limitations

Every CNC machine has a maximum power and torque threshold. As the material removal rate increases, cutting forces rise accordingly. If these forces exceed the spindle’s available torque, the machine may experience sudden stoppages or even damage to the drivetrain and spindle system.

4.2 Vibration (Chatter) and System Rigidity

Operating at high MRR levels intensifies the interaction between the cutting tool and the workpiece, generating mechanical vibrations known as chatter. If the fixturing system or the machine structure lacks sufficient rigidity, these vibrations will severely degrade surface finish and can cause immediate tool chipping or breakage. This is why toolpath optimization plays a critical role in maintaining machining stability under high cutting loads.

4.3 Heat Generation and Chip Evacuation Challenges

Higher material removal rates inevitably lead to significant heat generation within a short period of time. If chips are not evacuated efficiently, heat accumulates rapidly in the cutting zone, reducing tool hardness and potentially causing thermal deformation of the workpiece. Effective chip control and cooling strategies are therefore essential when pushing MRR to higher levels.

5. Toolpath Optimization with VoluMill Technology

Faced with physical limitations, traditional machining methods often have to settle for moderate MRR levels to ensure process safety. However, the introduction of VoluMill has completely changed the game.

5.1 What Is VoluMill?

VoluMill is a high-performance toolpath solution built on principles of material science and machine dynamics. Instead of generating simple parallel or concentric toolpaths, VoluMill leverages intelligent algorithms to create smooth, adaptive cutting paths that maintain a constant load on the cutting tool throughout the machining process.

5.2 Principle of Maintaining a Constant Tool Engagement Angle

One of the main reasons tools tend to break during high-MRR roughing is the sudden change in the tool engagement angle (Arc of Contact) at corners. VoluMill eliminates this issue by automatically adjusting the toolpath so that the contact area between the cutter and the material remains consistent. This allows engineers to confidently push feed rates to their maximum limits without worrying about force spikes or shock loading.

5.3 Maximizing the Effective Cutting Edge Length

With conventional toolpaths, engineers often apply shallow axial depths of cut (small ap) combined with wide radial engagements (large ae). VoluMill promotes the opposite strategy: deep axial cuts using the full length of the cutting edge combined with a small radial step-over. This approach distributes heat evenly along the tool body, reduces localized wear, and enables significantly higher material removal rates, often multiple times greater than traditional machining methods.

6. Outstanding Benefits of Applying VoluMill in Manufacturing

Integrating VoluMill into the production workflow delivers breakthrough, measurable improvements in machining performance and operational efficiency for manufacturers.

6.1 Maximizing Material Removal Rate (MRR)

Thanks to its superior cutting load control, VoluMill enables CNC machines to achieve MRR levels unattainable by conventional machining strategies. In practice, roughing productivity can increase by 200% to 500% after transitioning to VoluMill.

6.2 Extended Cutting Tool Life

By eliminating sudden force shocks and maintaining consistent chip thickness for better thermal control, cutting tools experience significantly less wear. As a result, tool life is dramatically extended, allowing manufacturers to save substantial costs on monthly tool replacement.

6.3 Protection of CNC Machine Infrastructure

VoluMill toolpaths are designed with smooth, continuous arcs, minimizing abrupt stops or sharp directional changes. This reduces stress on the spindle and linear axes, ensures smoother machine operation, and lowers long-term maintenance and repair costs.

6.4 Excellent Compatibility and Integration

Another key advantage of VoluMill is its seamless integration with leading CAM software platforms. This allows CNC engineers and manufacturers to deploy and transfer the technology quickly without significantly disrupting existing workflows.

7. Frequently Asked Questions about MRR

To help you reinforce your understanding of what CNC MRR is, SDE Tech has compiled the most frequently asked questions from our customers.

7.1 Does increasing MRR with VoluMill affect the durability of the CNC spindle?

On the contrary, VoluMill provides better spindle protection. By maintaining a stable cutting load and eliminating sudden directional changes, the spindle avoids instantaneous overload conditions. This allows CNC machines to operate more smoothly and reliably compared to traditional zigzag toolpaths.

7.2 Is VoluMill effective only for soft materials like aluminum, or also for hard materials?

VoluMill is extremely effective for hard and difficult-to-machine materials such as alloy steels, Inconel, and Titanium. For these materials, precise control of heat generation and cutting forces is critical, and VoluMill outperforms conventional machining strategies by a wide margin.

7.3 Can standard MRR formulas be applied when using VoluMill?

Basic MRR formulas can still be used to estimate the removed material volume. However, in practice, VoluMill enables the use of much higher input parameters (such as axial depth of cut ap and feed rate Vf) than those recommended in standard cutting tool catalogs, thanks to its intelligent machining strategy.

Optimizing CNC MRR in combination with VoluMill technology has become a critical requirement for manufacturing enterprises seeking to increase productivity, reduce costs, and build a sustainable competitive advantage. To fully unlock the potential of your CNC machine fleet, contact SDE Tech today for professional consultation and an in-depth VoluMill demo.

SDE Tech Contact Information:

- Email: sales@sde.vn

- Hotline/Zalo: 085 256 2615 – 0909 107 719

Register to become an authorized VoluMill distributor, leave your information, and SDE Tech will contact you shortly.

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어