How can you create breakthrough products as complexity continues to rise while development timelines grow ever tighter? The answer lies in Simcenter STAR-CCM+ 2510. With intelligent workflow optimization capabilities, Simcenter STAR-CCM+ 2510 empowers engineers to innovate freely while maintaining absolute confidence in simulation results. Join SDE Tech as we explore the “golden” features of this release—from advanced EV thermal management to cutting-edge GPU acceleration—that enable you to turn even the boldest ideas into reality.

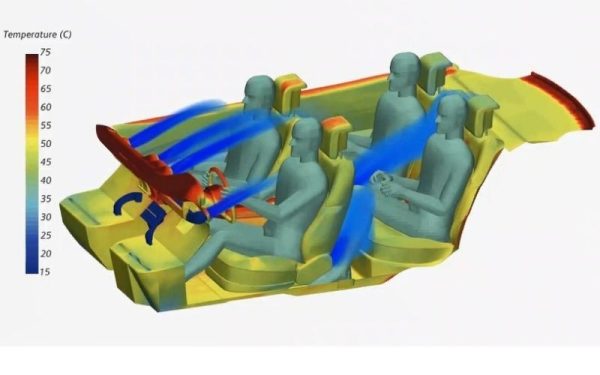

1. Passenger Thermal Comfort Simulation

For electric vehicles (EVs), balancing energy efficiency and passenger comfort is a complex challenge. Heating or cooling the cabin consumes a significant amount of energy, directly impacting vehicle driving range. In the past, simulating transient cabin temperature behavior often required complex co-simulation workflows with third-party tools.

With Simcenter STAR-CCM+ 2510, this barrier has been removed. The software now natively integrates advanced passenger thermal comfort models—such as Fiala and Berkeley—directly within the CFD environment.

This enables engineers to simulate the full transient behavior of the HVAC system alongside human physiological responses within a single, unified workflow. As a result, you can accurately evaluate the trade-off between energy consumption and thermal comfort, allowing you to make well-informed design decisions for optimal Vehicle Thermal Management (VTM) systems—without relying on intermediate software.

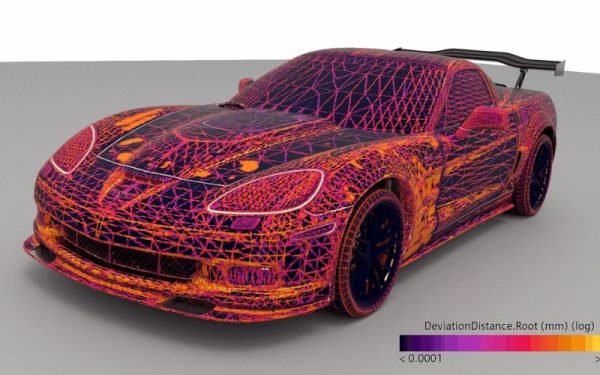

2. Topology Optimization — 3× More Stable Performance

Topology Optimization is a powerful tool for identifying optimal product geometries, but selecting the right penalty strategy has traditionally been a major challenge. An incorrect choice can lead to solver instability or constraint overshoot, compromising result quality.

Simcenter STAR-CCM+ 2510 introduces Dynamic Penalty Update, a major advancement that addresses this issue head-on. By leveraging an Augmented Lagrangian approach, the software automatically adjusts penalty factors throughout the optimization process—eliminating the need for manual tuning. This enhancement delivers up to three times faster optimization with significantly improved numerical stability, even for highly constrained and complex optimization problems. Engineers can now focus on design innovation with greater confidence in both convergence and results.

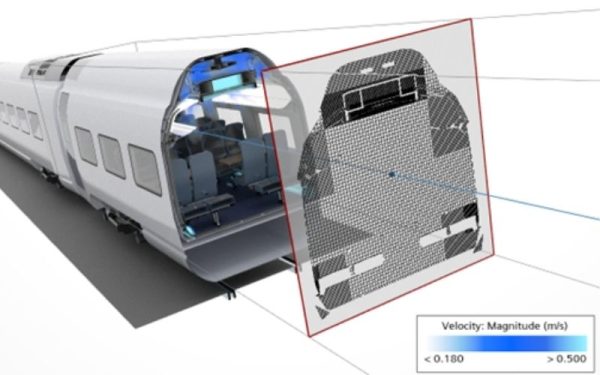

3. 50% Faster Surface Wrapping

Handling dirty or overly complex CAD data to generate a closed, manifold surface has long been a major bottleneck in CFD workflows. Siemens’ Surface Wrapper technology—already an industry benchmark—has now been taken to the next level.

With Simcenter STAR-CCM+ 2510, Phase 2 of the MPI Surface Wrapper has been fully implemented. The surface wrapping process is now completely parallelized across multiple processors, unlocking a significant boost in performance. Benchmark results show that surface mesh generation time can be reduced by up to 50% compared to previous versions. This improvement allows engineers to move from CAD data to simulation-ready models in minutes instead of hours, dramatically accelerating the overall CFD workflow and time to insight.

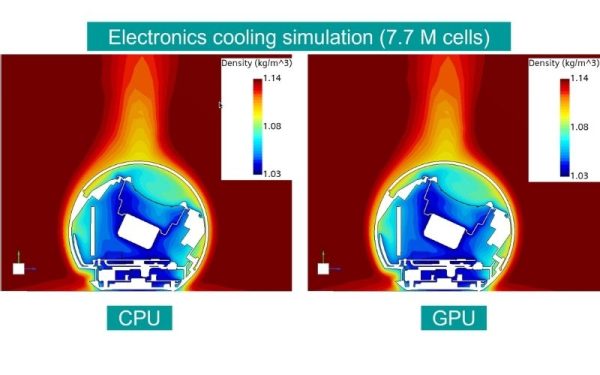

4. Breakthrough Performance with GPU Acceleration and Advanced SPH Enhancements

4.1 GPU Acceleration for Rotorcraft Simulations

Simulating complex rotating systems such as rotorcraft traditionally demands massive CPU resources and long turnaround times. With Simcenter STAR-CCM+ 2510, the Virtual Disk model can now run directly on GPU. This advancement dramatically reduces simulation time while maintaining accuracy comparable to CPU-based solvers. As a result, engineers can efficiently evaluate hundreds of design variants in a fraction of the time, significantly accelerating the design exploration and optimization process for aerospace and rotating machinery applications.

4.2 Local Particle Refinement for SPH

The Smoothed Particle Hydrodynamics (SPH) method is widely used for applications such as gearbox lubrication, oil splash, and free-surface flows. However, applying uniformly fine particles across the entire domain often leads to unnecessary computational cost.

Simcenter STAR-CCM+ 2510 introduces Local Particle Refinement, enabling engineers to define specific regions—such as boxes, cylinders, or spheres—where higher particle resolution is required. The software refines particles only within these critical zones, while keeping a coarser resolution elsewhere. This targeted refinement strategy significantly reduces computational expense without compromising accuracy in areas that matter most, delivering a more efficient and scalable SPH simulation workflow.

5. Enhanced Support for Electric Machine (E-Machine) Design

Radial flux electric machines account for more than 95% of the global electric motor market. Traditionally, the simulation workflow between electromagnetic (EMAG) tools and thermal/CFD analysis has been fragmented, leading to data inconsistencies and inefficiencies.

With Simcenter STAR-CCM+ 2510, this barrier is removed. Engineers can now import electric motor designs directly using the Simcenter Data eXchange (SCDX) file format. This format is fully compatible across the Simcenter ecosystem, ensuring seamless transfer of CAD geometry and physical data between electromagnetic and thermal simulation environments. As a result, electrical and thermal design teams can work in a synchronized, integrated workflow, significantly improving collaboration, reducing iteration time, and accelerating the development of high-performance electric machines.

6. Expanding Particle-Based Simulation Capabilities with Prometech

In addition to the built-in SPH (Smoothed Particle Hydrodynamics) capabilities available in Simcenter STAR-CCM+, SDE Tech also delivers advanced solutions from Prometech – a leading technology partner specializing in particle-based simulation and high-performance computing (HPC).

If your organization is facing highly specialized challenges such as:

- Complex free-surface flows (high-viscosity fluids, chemical mixing processes)

- Fluid–gas–solid interactions with large deformations

- Requirements for ultra-fast solver performance on dedicated GPU platforms

then Prometech solutions such as Particleworks and Granuleworks provide a powerful answer. These tools integrate seamlessly with the Siemens simulation ecosystem, creating strong synergy and enabling engineers to solve physical phenomena that are extremely difficult or impractical for traditional mesh-based methods.

Simcenter STAR-CCM+ 2510 is not just a feature update—it represents a major leap in simulation performance. By eliminating manual bottlenecks and fully leveraging modern hardware architectures, this release empowers engineers to turn engineering complexity into a true competitive advantage. SDE Tech is ready to support you in upgrading and unlocking the full potential of Simcenter STAR-CCM+. Contact us today for expert consultation and a tailored digital transformation roadmap for your business.

- Email: sales@sde.vn

- Hotline/Zalo: 085 256 2615 – 0909 107 719

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어