USING SIMCENTER FLOEFD IN SPORTS

Voxdale is a design and engineering company based in Belgium. We believe that sports and technology always go hand in hand. Especially when you are looking for marginal gains that can make the biggest impact, which can be the difference between winning and losing. By using Simcenter FLOEFD™, CFD (Computational Fluid Dynamics), we are always at the forefront of technological innovation, particularly in sports simulation.

Helmet Optimization

For us, sports are all about emotions. Last year, during the time-trial stage of the Tour de France, this moment remained fresh in the memories of many cycling fans. During this time-trial, Roglic lost what seemed to be a certain victory when his competitor Pogacar took the lead in the overall classification at La Planche des Belles Filles.

Immediately after the race, Roglic’s helmet became a topic of debate. Did the Slovenian cyclist have an unlucky day? Or could the helmet have been the reason for his loss?

The helmet alone could not be the only factor causing the difference between the two cyclists. Both the Jumbo-Visma professional cycling team and helmet manufacturer Lazer carried out extensive testing to improve the rider’s and his equipment’s aerodynamic performance. With Voxdale’s help, Lazer modified the design and improved the helmet’s aerodynamics. The results of this optimization were evident in the Men’s Time-Trial at the Tokyo Olympics earlier this year, where Roglic won the gold medal!

Bobsleigh Optimization

Due to the COVID-19 pandemic, the Winter Olympics were postponed to 2022. A great opportunity for sports enthusiasts, as Voxdale has been working with several national bobsleigh teams for years to develop and optimize the athletes’ equipment.

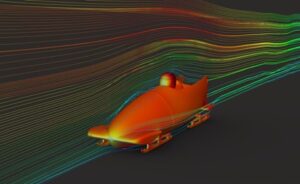

Once a bobsleigh reaches 40 km/h on just 50 meters of ice, gravity acts as the accelerating force. From that point on, aerodynamics mainly determines the sled’s speed. To achieve maximum performance, we used Simcenter FLOEFD to optimize the bobsleigh design.

We worked to minimize frontal surface area and drag coefficient. CFD is a powerful tool for comparing different design concepts at this stage, as it allows detailed visualization and study of flow structures. It also allows performing experiments under approximate conditions that are difficult to replicate in real life, such as low temperatures and high speeds.

Bernico Uses CFD for Surfing Boats

Just a small step is needed to convert water from solid to liquid, especially in CFD! Bernico International manufactures custom electric boats for recreational and racing purposes. For the new racing boat concept, Bernico hired Voxdale to finalize the design and achieve peak performance.

Optimizing the boat’s aerodynamic efficiency is challenging due to the combination of fluid dynamics above and below the waterline. For this particular issue, Voxdale engineers used the Free Surface feature in Simcenter FLOEFD, allowing them to investigate wake effects behind the boat and optimize the hull under real-life conditions.

Using Digital Twins

Voxdale has a rich history of using CFD in sports, especially in cycling. Did you know that some of the fastest bicycles in the professional peloton were developed in Belgium with Voxdale’s help? Together with Ridley’s R&D department, one of Europe’s leading bicycle manufacturers, we worked on a new bike frame optimized for road racing.

At speeds of 45 km/h on flat terrain, 90% of a cyclist’s total energy is spent overcoming aerodynamic drag. Because drag increases quadratically with speed, optimizing the athlete’s equipment for maximum aerodynamic efficiency is critical.

The design process for this new bike perfectly illustrates how modern technologies combine. Voxdale started by creating a digital 3D bike for analysis and optimization using CFD. Achieving perfect results in a headwind in real life is impractical.

Simcenter FLOEFD can simulate airflow from multiple angles affecting cycling speed. We can then analyze its detailed impact on each bike component. During the CFD design phase, essential features were established, giving Ridley Noah Fast an advantage over competitors.

Next, the CAD model was brought to real life using 3D-printed parts to create a comprehensive wind tunnel model. Initial simulations were validated in real conditions. After final adjustments, Ridley could begin frame production.

CFD Creates the Perfect Bike

Using CFD in a project like this is a game-changer. Aerodynamics has a major impact, especially in cycling. Think about riders facing less resistance while riding together, or the seamless integration of a specific helmet into the athlete’s position.

CFD allows focus on the bigger picture. Every component of this particular bike is optimized to work with the rest of the frame. The handlebars transition seamlessly into the top tube. Additionally, the lower down tube is designed with a 3D-specific shape to distribute wind drag.

As a result, the frame is optimized to reduce the impact of rough roads, making it one of the best bikes!

Source: Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was founded in 2014. By 2018, we proudly became a Smart Expert Partner – the leading partner of Siemens Digital Industries Software in Southeast Asia – Pacific for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어