MODAL SURVEY TEST IN AEROSPACE WITH SIMCENTER

Courtesy Airbus Defense & Space: Illustration of the Bartolomeo platform designed to expand ISS utilization

All structures have natural frequencies, which are often the most critical characteristics, especially regarding dynamic responses. Typically, vibrations must be surveyed to quantify structural responses and assess their impact on factors such as performance and fatigue.

Modal testing is a very useful and widely applied technique to verify and examine this state, including natural frequencies, mode shapes, and damping, helping engineers understand how a design will respond to various dynamic loads.

In the aerospace industry, this technique is also known as modal survey testing, aimed at calibrating and enhancing the accuracy of finite element (FE) dynamic models of spacecraft and space launchers. In all cases, validated models play a crucial role in predicting launcher vibration characteristics, aeroelastic stability, and dynamic environments experienced by payloads and onboard equipment during launch.

Images from NASA: Modal survey testing on Ares rocket (left), Challenger Shuttle (center), and SLS super rocket (right)

A modal survey test involves applying excitation forces using an electrodynamic shaker, or in some cases, a modal impact hammer at carefully selected input points. For shaker excitation, the burst random excitation method is often used because it is fast and efficient.

When higher excitation levels are required or to evaluate nonlinear characteristics, sine excitation techniques are applied. Forces are measured during testing along with response accelerations at multiple positions throughout the structure. The spacecraft is mounted under known boundary conditions—either fixed, free-free, or a combination. During excitation, FRFs are measured.

After testing, modal curve-fitting technology is applied to extract modal information: resonance frequencies, damping coefficients, and mode shapes. Test results are used to validate the FE model and correlate frequencies, mode shapes, and damping assumptions. Key mode shapes and frequencies are critical contributors to launcher/spacecraft interface loads and internal loads.

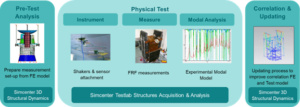

This process is illustrated in the diagram below. It shows how initial spacecraft FE models can be used in Simcenter 3D Structural Dynamics to perform pre-test analysis and optimally design the test campaign. Then, Simcenter Testlab and Simcenter SCADAS are used to measure FRF accuracy and reliability and determine the best experimental model precisely.

Experimental results are further leveraged to correlate preliminary models with test outcomes and update FE models to better reflect reality.

Different stages of the modal survey test process: from test preparation, execution, analysis, to reporting

A typical example of a modal survey test is the Bartolomeo project by Airbus Defense & Space, executed by Deutsches Zentrum für Luft- und Raumfahrt (DLR). The Simcenter SCADAS Mobile hardware was used as the primary measurement device for the modal survey test to update the FE simulation model of the Bartolomeo platform. This allowed the team to simulate and predict aspects that could only be analyzed through simulation, such as platform interaction with the launcher.

Source: Siemens

Công ty TNHH Công Nghệ Số SDE (SDE TECH) was established in 2014. By 2018, we proudly became a Smart Expert Partner—the leading partner of Siemens Digital Industries Software in the Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter management solutions. Enterprises and customers can contact SDE TECH at:

Enterprises and customers can contact SDE TECH at:

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어