SYSTEM-IN-THE-LOOP TESTING WITH SIMCENTER

Bridging the gap between Digital Twin and physical hardware with system-in-the-loop testing using Simcenter

Automotive engineers today face a tough question: while vehicle engineering complexity has exploded, the expected time-to-market has dramatically shortened.

Engineers must consider more factors in vehicle development than ever before:

- More vehicle generations. You’re not just building a single car; you’re building multiple variants of the same vehicle (different powertrains, etc.). This makes the work of test or integration engineers much more challenging, with more situations, environments, and components to test in a shorter time.

- Increased system integration. As vehicle complexity grows, so does the number of interrelated systems. Ensuring all systems function correctly and are integrated is critical.

With increasing vehicle generations and complexity, late detection of integration issues during the design phase can be costly and impact time-to-market.

At Simcenter Engineering Services, we believe that a seamless combination of testing and simulation is key to tackling these challenges.

The shift to MBD

To avoid late-stage integration troubleshooting, manufacturers are shifting focus from testing and fixing to system simulation.

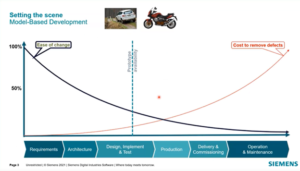

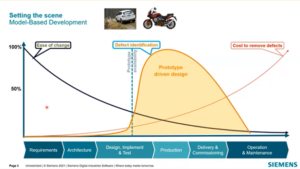

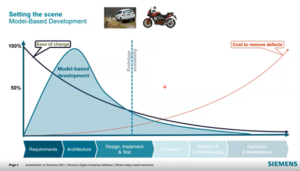

Model-Based Development (MBD) pushes the boundaries of vehicle performance evaluation, enabling engineers to address integration issues much earlier in the development process through simulation. Explore MBD further in the diagrams below:

The image above illustrates a flat V-cycle from design requirements to the final vehicle. Late changes in the V-cycle are costly. Identifying issues earlier, when defining requirements, architecture, etc., is easier, less expensive, and more efficient.

If a company only makes changes once a physical prototype exists, costs rise significantly.

Looking from right to left along the V-cycle, full-vehicle MBD addresses most issues. However, you cannot do everything with models alone. Some parameters, such as NVH friction values or sliding issues, are hard to control without testing. Predictions can be made using design, but actual values require experimentation.

In the webinar “System-in-the-loop Testing – A Revolution in Vehicle Integration”, we address the critical question:

How can engineers bridge the gap between physical hardware and digital twins?

System-in-the-loop testing – a revolution in vehicle integration

Watch this webinar to learn how Simcenter Engineering Services’ system-in-the-loop approach can help you:

- Integrate subsystems to reduce risk by combining simulation and testing.

- Upgrade test benches to XiL to evaluate vehicle generations more efficiently.

- Use test data to build, validate, improve, and drive simulation models.

- Leverage simulation models to identify, validate, and complement test procedures and data.

By connecting stages of product development, manufacturers and suppliers can accelerate time-to-market, manage system engineering complexity, and improve vehicle performance.

Source: Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was founded in 2014. By 2018, we proudly became a Smart Expert Partner – the leading partner of Siemens Digital Industries Software in Southeast Asia – Pacific for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter management solutions.

For inquiries, contact SDE TECH as follows:

For inquiries, contact SDE TECH as follows:

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어