In the precision machining industry, even a minor collision on a CNC machine can result in thousands of dollars in damage—not to mention delivery delays and lost customer trust. Many companies believe they are already protected by the built-in verification tools they use, but real-world incidents often prove otherwise. SDE Tech invites you to uncover the five most common myths about CNC simulation software and understand why a dedicated solution like MANUSsim serves as a true shield for safeguarding your profitability.

1. CAM Simulation Equals Real G-code Simulation

This is the most dangerous misconception of all. Most CAM software vendors claim to offer “simulation” capabilities. However, in reality, the majority of these simulations are based only on intermediate toolpath data (such as APT or CL data), not on the actual G-code that will be executed on the machine.

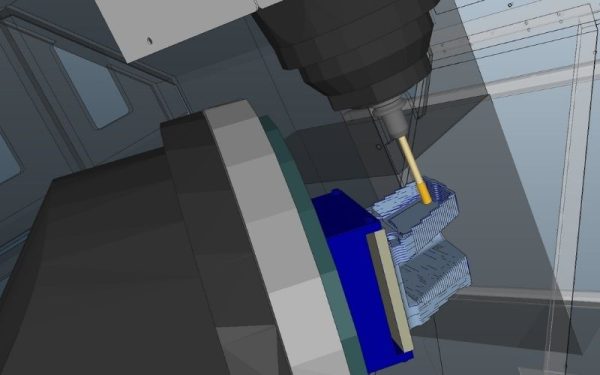

The truth is: If a CNC simulation tool does not read and accurately interpret real G-code, it cannot be considered a reliable verification solution. Intermediate data inside the CAM system may look perfect, but once the Post-processor generates the G-code, syntax errors or coordinate deviations can easily occur. These issues may cause the CNC machine to behave unexpectedly, leading to crashes and costly accidents. Only true G-code–based simulation (such as MANUSsim) can represent 100% of the real machine behavior.

Related article: Building a CNC Post-Processor Workflow with MANUSsim

2. Using Third-Party CNC Simulation Software Is Complicated and Risky

Many engineers are hesitant to change, believing that exporting data to a standalone simulation tool is time-consuming and prone to errors.

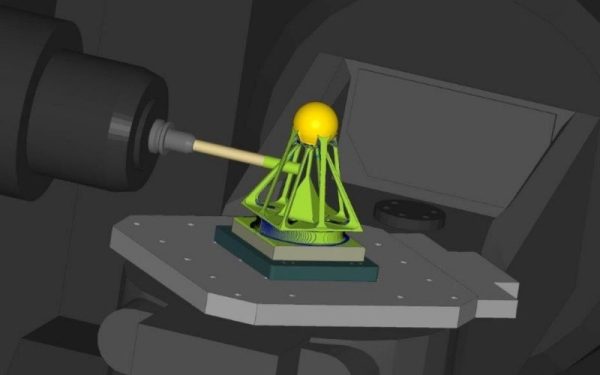

The truth is: Modern professional CNC simulation solutions such as MANUSsim are built with extremely powerful integration capabilities. They provide dedicated plugins that connect directly to the most popular CAM systems (including Siemens NX, Mastercam, and others). With just a few clicks, all critical data—3D models, cutting tools, fixtures, and coordinate systems—are transferred seamlessly into the simulation environment.

Moreover, using a third-party simulation tool helps free up CAM licenses. Your team can program new parts in the CAM system while simultaneously running simulations of previous jobs in MANUSsim—in parallel, without workflow interruptions. This significantly improves productivity and maximizes software investment efficiency.

3. CNC Simulation Is Only Necessary for Complex Parts

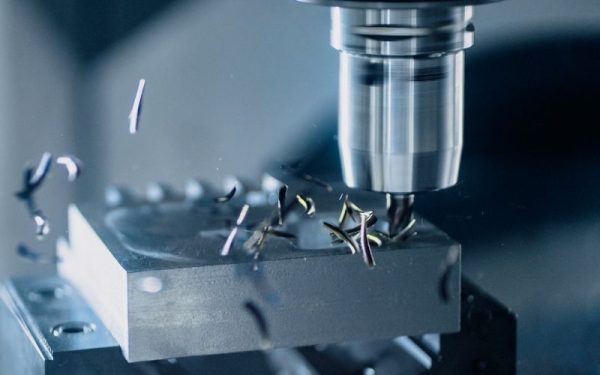

“This part is simple—just 2D milling. Why bother simulating?” This mindset is often the root cause of the most costly and avoidable incidents.

The truth is: CNC machine collisions do not discriminate between simple and complex parts. A single typo in the G-code, an incorrect tool offset, or an unsafe retract motion can easily cause the spindle to crash into the workpiece or fixture. SDE Tech strongly recommends adopting a standardized verification process: every NC program must be checked in a CNC simulation software before being released to the shop floor, regardless of its perceived simplicity. This discipline is essential to ensuring machine safety, protecting tooling, and safeguarding production schedules.

4. Investing in CNC Simulation Software Is a Waste of Money

Many business owners view CNC simulation software as a luxury expense rather than a critical investment.

The truth is: Let’s look at it from an economic perspective. The cost of repairing a damaged spindle after a crash, the value of scrapped workpieces, and potential penalties for delayed delivery can easily add up to far more than the license cost of CNC simulation software. MANUSsim is not merely a risk insurance tool—it is a profit-generating solution. By preventing costly mistakes before they reach the shop floor, it eliminates waste, protects capital equipment, and safeguards delivery commitments, delivering a clear and measurable return on investment.

5. Simulation Is Only for Error Checking and Offers No Additional Value

If you believe CNC simulation software is only useful for “debugging,” you are overlooking at least 50% of its true value.

The truth is: A modern CNC simulation solution must go beyond error detection and actively support process optimization. MANUSsim not only identifies collisions, but also helps you:

- Optimize cutting speed (Feed Optimization): Automatically adjusts feed rates based on actual material removal, reducing overall machining time.

- Eliminate redundant toolpaths: Removes unnecessary air cuts that add no value but consume time.

- Control cutting conditions: Ensures the spindle and cutting tools operate within safe load limits, preventing overload and premature wear.

6. Frequently Asked Questions (FAQ)

6.1 Why shouldn’t I fully rely on the built-in simulation in CAM software?

Because most CAM systems only simulate internal toolpath data (CL Data). The conversion process from CL Data to actual G-code via the Post Processor can introduce errors that CAM simulation cannot detect. Only true G-code simulation can guarantee accuracy and reflect the real behavior of the CNC machine.

6.2 Is MANUSsim difficult to learn and use?

Not at all. With its intuitive interface and ready-to-use integration plugins, a new engineer typically needs only about half a day to become familiar and work effectively. In addition, SDE Tech’s technical team is always available to provide detailed training and ongoing support.

6.3 Can CNC simulation software help reduce machining time?

Yes. Beyond risk prevention, MANUSsim’s optimization features intelligently adjust feed rates and cutting conditions, helping reduce cycle time by 10–20%, depending on the part and machining strategy.

Equipping your shop with true G-code simulation software is a mandatory step in modern manufacturing. With a reasonable investment cost and absolute collision prevention capability, MANUSsim is the optimal solution for protecting your machines and maximizing productivity. Contact SDE Tech today for a free demo and experience the difference firsthand.

- Email: sales@sde.vn

- Hotline/Zalo: 085 256 2615 – 0909 107 719

*Content compiled from: manusnc.com

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어