7 WAYS ARTIFICIAL INTELLIGENCE WILL TRANSFORM ENGINEERING IN THE FUTURE

In this blog, we explore how engineers are beginning to use machine learning and artificial intelligence to amplify their knowledge, increase the amount of knowledge gained through simulation and testing, and transfer accumulated insights across projects.

We also aim to dispel some misconceptions about AI and ML and demonstrate that implementing these techniques provides a competitive advantage over peers who do not use them. Although I have previously discussed how AI will impact engineers in the future, the truth is that it is already providing significant benefits to engineers today.

-

Interpreting Results

Engineering simulations and tests often produce massive amounts of data. While it is common to reduce this information to a few key parameters describing design performance, experienced engineers still have the ability to visually interpret these large datasets (often rich three-dimensional fields that change over time).

This enables the identification of critical features such as vortices or separation bubbles in flow simulations, or stress concentration and thermal gradient fields—factors that directly impact design performance.

Design teams often employ less experienced engineers to handle the bulk of simulation tasks (meshing, setup, computation, and post-processing) or physical testing. Senior engineers then review the results and make decisions.

The problem is that 3D result fields contain a wealth of valuable information. While reducing design performance to a few key parameters is convenient, optimizing based on a limited set of parameters may show which design performs better than others, but not necessarily why.

To address this, Simcenter customers now use machine learning to scan results from thousands of previous simulations and generate algorithms to identify flow features (or stress concentrations or other factors) that most significantly affect product performance—features that even the most experienced engineers might not detect.

-

Simulation Speed

Engineering innovation speed is always limited by the availability of resources such as technical expertise or computational power.

Manually identifying individual components in an assembly of connected CAD parts can be extremely time-consuming. Unfortunately, this step is unavoidable if you want to assign local mesh properties, physical boundary conditions, or identify parts for post-processing reports.

Many simulations involve assembling complex individual CAD parts

For example, in an aerodynamic simulation, a radiator mesh panel is treated differently than a rotating alloy wheel. Using machine learning from pre-classified simulation models, AI can be trained to identify individual CAD components based on their shape and attached metadata.

AI can be trained to automatically recognize parts from their shape and metadata

-

Instant Insights

As engineers, our job is to answer the question “what if?”—the question that drives engineering design. Any engineer has felt the frustration of presenting full simulation and test results during a design review, only to be asked, “What if we tried this instead?”—a scenario you hadn’t considered.

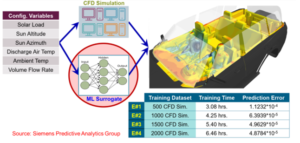

In such cases, machine learning algorithms can accumulate knowledge from previous simulations and predict the outcomes of design changes, including 3D vector and scalar fields. This allows engineers to see possible results of their hypotheses in real time. If the training database is sufficient, the difference between AI predictions and actual simulation results can be negligible.

AI can be trained to predict the outcomes of design changes or scenarios with high accuracy

This approach should be applied cautiously, but it allows the immediate elimination of infeasible solutions and enables engineers to decide next steps instantly rather than waiting for another review meeting.

This approach is not limited to static or steady-state simulations: for example, Simcenter has been successfully applied (and accurately) to moving engine components across multiple rotational positions.

-

Enhanced Design Exploration

An extension of the previous idea (machine learning predicting design changes in real time) is that AI can accelerate exploratory studies and design optimization. Typically, these studies progress by testing a series of design scenarios, rejecting any designs that fail performance criteria.

Using AI and ML, we can eliminate poor designs to narrow the exploration space before running any simulations. This allows engineers to focus computational resources on finding valid design scenarios. Modern design exploration techniques help identify issues and adapt accordingly.

-

Knowledge Transfer

Accumulated knowledge guides all design processes. In early stages, knowledge is often obtained from low-fidelity simulations (or physical tests) to predict key attributes like pressure drop or flow rate (basically, scope calculations).

While simulation and test fidelity typically increase in later stages, some design parameters are fixed from the initial simple simulations throughout subsequent design iterations. Months later, after extensive testing and simulations, one may wonder, “What if we hadn’t locked that parameter so early?”

AI allows you to map all knowledge gained across the design process for application in the next design phase, helping engineers predict the impact of parameter changes. This “transfer learning” enables better-informed design decisions later.

-

No More Wasted Data

Failure is part of success in innovation, and engineering is a continuous improvement process. Engineers improve existing designs through incremental changes, each aimed at better performance. Every successful product results from many iterations, each gradually enhancing performance.

The problem is that for every successful design iteration, there are numerous “failed iterations.” There are countless ways to discard changes that don’t improve performance. Predicting which changes will improve or degrade the product is essential. Poor design choices must be eliminated. Lessons from early failures often influence the overall design direction for future projects.

Until now, data from these “forgotten” simulations was often discarded or stored and neglected. Yet all this data is extremely valuable for training machine learning algorithms, as we know that learning comes from both successes and failures.

-

Learning from Simulation AND Testing

Although simulations and testing are different—or even opposing—domains, any sharp engineer makes decisions based on insights from both digital and physical experiments. Combining this data is often difficult, involving compromises when mapping from one domain to another. AI offers the opportunity to integrate information from multiple simulations and tests via machine learning into a single model, improving overall data predictability.

Of course, these are predictions based on recent experience observing our customers using AI and ML to improve the quality and quantity of their simulation experiences.

Watch the video to see how AI and ML are applied in the automotive industry:

https://www.youtube.com/watch?v=SoxwLAT0DL8Source: Stephen Ferguson – Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was established in 2014. By 2018, we became a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

For businesses and customers, please contact SDE TECH using the information below:

For businesses and customers, please contact SDE TECH using the information below:

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어