TOKAMAK ENERGY USES SOLID EDGE AND TEAMCENTER TO ADDRESS GLOBAL ENERGY CHALLENGES

Where do you start when tackling one of humanity’s greatest engineering challenges? Tokamak Energy is addressing this question by developing sustainable fusion energy through tokamak machines. But first, what is a tokamak?

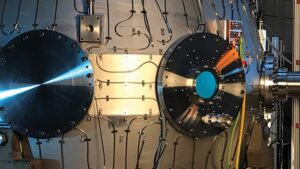

A tokamak is a magnetic confinement device that uses magnetic fields to contain plasma, developing and producing controlled fusion energy. Essentially, it creates and contains a star.

Tokamak Energy’s challenge was to build a compact tokamak just a few meters wide, compared to publicly-funded versions as tall as 20 stories. They not only had to design and manufacture a compact tokamak but also develop a solution to demonstrate breakthrough physics.

Solving the World’s Toughest Engineering Challenges

Tokamak Energy produced two laboratory prototypes. The first, ST25 HTS, demonstrated the use of high-temperature superconducting (HTS) magnets. The second, ST40, used copper magnets, presenting a major engineering challenge as Tokamak Energy aimed for exceptionally strong magnetic fields of up to 3 Tesla at the plasma core. Engineers understood the physics, but the big question was how to contain and control plasma at extreme temperatures and pressures.

They solved this by limiting the maximum pulse length for the magnetic field to about one second to prevent copper overheating. Once this was resolved, devices could operate longer using high-temperature superconductors. Tokamak Energy achieved plasma temperatures of 15 million °C, hotter than the sun’s core, ultimately reaching 100 million °C.

Fabricating the 50-ton ST40 from specialized copper and steel alloys required corrosion resistance, heat resistance, low magnetic permeability, high electrical conductivity, and structural stability. Tokamak Energy used Solid Edge and Teamcenter, both part of the Siemens Xcelerator portfolio, with support and guidance from Siemens Digital Industries’ OnePLM software solutions partner to accomplish this.

Bill Huang, Senior Engineer at Tokamak Energy, said: “There were a range of design challenges to solve, so we were looking for a standard tool with exceptional parametric capability, and Solid Edge met this need.”

Solid Edge ensured the handling of extremely complex product designs thanks to precision and structural integrity of the tokamak. Engineers could simulate part stresses, evaluate forces and constraints, and capture critical knowledge around potential displacements and movements. This accelerated overall development, allowing engineers and design teams to identify potential issues with Solid Edge.

Combining the Virtual and Physical Worlds

Collaboration and rapid decision-making were key to success, and Solid Edge enabled multiple engineers to work on different development aspects simultaneously. By highlighting potential issues and identifying required components, Tokamak Energy could plan production and assembly before deployment.

“We started with no hardware and created everything in the virtual world. With Solid Edge, we can communicate at multiple levels and share geometry to design new parts. Decisions that once took days can now be made in minutes.”

Damian Lockley, Mechanical Design Advisor, Tokamak Energy

As an investment-focused company, Tokamak Energy constantly sets requirements for building and improving prototypes. With Xcelerator, they continue to develop and innovate with rapid updates, better decision-making, and enhanced collabora

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어