INTEGRATING HEEDS IN SIMCENTER 3D

Welcome back to the Design for Purpose series. Previously, we explored topics such as lattice structure capabilities, Multimech integration, and the benefits of virtual testing and simulation related to sustainable manufacturing. Now, we will explore the final step of the product lifecycle development process.

Today, consumers are willing to pay more for environmentally friendly products. This is great news for companies that want to protect the environment and are ready to modernize their design processes. Advanced design methods can significantly reduce energy consumption and eliminate scrap. While this is a goal for many engineers, HEEDS can make it a reality.

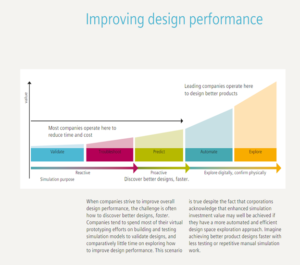

Figure 1. Redefining simulation strategies for innovation

HEEDS is a design exploration and optimization software that allows engineers to identify the most sustainable and efficient designs. It enables users to drive product innovation and accelerate product development by automating the analysis workflow.

Fully integrated within Siemens’ Simcenter 3D, HEEDS continues to maximize available hardware and software resources. The software explores design space efficiently for creative solutions and evaluates new concepts to ensure performance requirements are met. Integrating HEEDS saves significant time and resources, helping products reach the market faster.

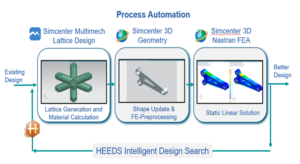

Figure 2. HEEDS – Automating design exploration and accelerating new product development

Unlike most traditional optimization tools that require expert knowledge and simplified models, HEEDS is easy for engineers and designers to unlock innovation. HEEDS includes proprietary Design Space Exploration functionality to efficiently identify design ideas that meet performance requirements. It automatically adjusts the search strategy as it learns more about the design space to find the optimal solution within a set timeframe.

HEEDS allows easy performance comparison across multiple designs, showing desired features and durability. Instead of the entire engineering team spending weeks creating optimized designs, HEEDS accomplishes this in just a few hours.

HEEDS supports visualization of performance trade-offs between competing objectives and constraints. Results are analyzed along with automatically generated charts, tables, graphs, and images to explore outcomes effectively. Many features in HEEDS enable the development of production-ready designs, creating a true digital twin.

HEEDS’ automated workflow facilitates rapid product development, integrating multiple technologies without custom scripting. Data is automatically shared among modeling and simulation products to assess performance trade-offs and design sustainability.

Fast optimization produces efficient, lightweight, structurally improved, and manufacturable designs. This process drastically reduces waste and lowers energy consumption throughout the product lifecycle.

Figure 3. Full integration of HEEDS with Simcenter

To demonstrate, consider the HEEDS demo below. Continuing with the UAV mold lattice structure we redesigned for additive manufacturing, we conduct a HEEDS study exploring 10 different design options.

The varying parameter is the lattice thickness, ranging from 0.2 mm to 0.5 mm. To determine the optimal design, Von-Mises stress output is compared, and the design with the lowest stress is selected. The demonstration workflow involves three simple steps.

First, create lattice structures with different widths. Second, import the lattice files generated in step 1 into Multimech for analysis and export to simulation once completed. Third, run the simulation on the UAV mold with automatically imported material properties.

With this workflow, creating a new study in HEEDS is easy. First, add gates to generate lattice structures and run simulations (Simcenter and Nastran gates), as well as analysis gates to import variations of each design simulation. Next, for each gate, add execution commands, input/output files, dependencies, and environmental variables.

Future study variables are defined, and feedback is generated. Files containing parameters are recorded and tagged so HEEDS can locate and record their values. The final step is creating a design set and response objectives. In this example, the ten designs with varying lattice thickness are evaluated to minimize stress.

https://video.mentor.com/embed/514b0192-2114-4fda-a24a-e968b8a1f051

As shown in the video, HEEDS provides a user-friendly automation process for simple and easy configuration. Although not clearly shown, creating tagged Macro files is recorded during Multimech export in NX. The design number tag is required to adjust file paths created by the Macro.

Integrating HEEDS with NX enables discovering better designs, increasing productivity, reducing waste, and lowering energy consumption. Now, you can see the full workflow of how NX, Multimech, Simcenter Simulation, and HEEDS integrate seamlessly for additive manufacturing processes. This workflow adapts to all designs and projects.

Design for Purpose can be applied to most projects. For example, a study on office chair designs can minimize costs and reduce foot pressure. The workflow is also used for vacuum studies to maximize suction force. Additionally, you can optimize heat sink designs to improve thermal insulation and reduce weight.

Source: Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was established in 2014. By 2018, we became a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in the Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어