Lattice Structure Design Capabilities in NX Design

Today, human life continues to improve thanks to the industrial revolution and continuous advances in science and technology. The world is gradually transforming by placing greater emphasis on sustainability in design in response to environmental impacts. This revolution is prevalent across all industries, especially automotive, aerospace, energy, and biomedical fields.

Although each industry serves different markets, products, and innovation approaches, they all share one common characteristic—manufacturing. The key to achieving design objectives is ensuring sustainable manufacturing processes.

At Siemens DISW, we enable users to apply their projects using new creative tools to modernize solutions and processes. We are confident in leading sustainable innovation by developing a comprehensive additive manufacturing lifecycle workflow.

Turn your ideas into reality in record time. Everything is within reach with enhanced NX design for additive manufacturing features, multi-physics integration, advanced simulation, and the continued development of HEEDS (design space exploration and optimization software).

This is the first article in a five-part series on the complete manufacturing lifecycle workflow that Siemens DISW aims to equip your business with.

The first tool introduced is the newly enhanced NX Lattice Design capability. Included in NX Design for Additive, this optional NX module helps users streamline the creation of complex lattice structures. Inspired by natural crystal formation, lattice structures are repeating arrangements of two- or three-dimensional microstructures.

These microstructures contain a network of beams—also known as struts—and nodes, or spheres. With the rise of additive manufacturing technologies, lattice structure techniques have evolved significantly in both functionality and adoption. The inherently customizable nature of lattices allows engineers to tailor designs to suit specific applications.

Integrating lattice structures into designs enables significant mass reduction, thereby lowering costs associated with material resources, machining processes, transportation, and energy consumption. While additive manufacturing reduces material waste by eliminating the need for tooling by-products, incorporating lattice structures also preserves material porosity.

Performance-oriented designs benefit from lattices with lower stiffness and the ability to withstand and recover from large deformations. They protect products by enhancing absorption of impact energy and severe vibrations. The strength-to-weight ratio can be significantly improved, and structural durability can be extended through virtual simulation and material testing of lattice designs using Multimechanics and HEEDS—topics to be explored in future articles.

Recognizing the benefits lattice engineering brings to design, Siemens NX provides users with three lattice structure command sets: graph-based structures, lattice structures, and triply periodic minimal surface (TPMS) structures. Each serves a distinct purpose and offers unique advantages.

TPMS-based lattice structures feature unit cells without intersections and possess topology generated by mathematical equations. Examples include the Schoen gyroid, Schwarz diamond, and Neovius structures. TPMS structures are typically self-supporting and offer high energy absorption capabilities. Below are several examples of TPMS structures.

Figure 1. Triply periodic minimal surface unit cells: (A) Schoen Gyroid, (B) Schwarz Diamond, (C) Neovius

Lattice body structures allow users to create three-dimensional repeating patterns within a part. With limitless combinations and capabilities, this option enables flexible design and easy customization. Examples of lattice body structures are shown below in Figure 2.

Figure 2. Body lattice applications provided by NX to support purpose-driven design

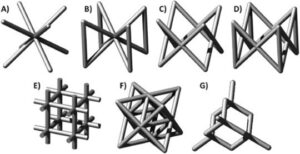

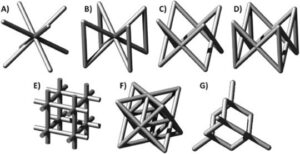

Graph-based structures are the most commonly referenced lattice type, consisting of tessellating sphere and strut configurations. Numerous unit cell arrangements are available, each possessing unique structural and thermal properties to drive design innovation. Several examples of graph-based structures are shown in Figure 3.

Figure 3. Graph-based lattice structures: (A) BCC, (B) BCCZ, (C) FCC, (D) FCCZ

With an understanding of what lattice structures are and their potential to optimize sustainable designs, we will examine an example of how lattice structures can be implemented in manufacturing to accelerate processes used to create parts across industries.

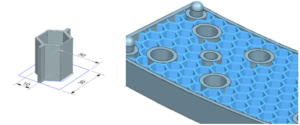

The part shown is an injection mold originally designed using traditional manufacturing methods. During implementation, the part is redesigned for additive manufacturing. These changes result in an environmentally friendly tool that is designed and produced in a shorter time frame, with reduced part weight and improved structural characteristics to extend service life.

NX capabilities such as synchronous and implicit modeling functions make designing and redesigning parts easier. Implicit modeling enables the creation of more robust part designs in significantly less time than traditional modeling. With implicit modeling, this part takes only minutes instead of hours.

Figure 4. Implementing implicit modeling and lattice structures in an injection mold

As shown, two lattice types are applied to the internal cavity of the part, illustrated in Figure 3. The first selected lattice is a Quad-Diametral (BCC) structure with a unit cell size of 6 mm and a strut diameter of 1 mm. The spheres are not merged but can be added at intersecting struts to enhance structural properties.

Optimal build orientation is established, and disconnected lattice regions are removed as necessary. What once took months to design can now be completed in minutes using these three simple steps. The second applied lattice type is a diamond TPMS structure.

This lattice is applied for comparison with the BCC graph-based lattice. After evaluating both, the BCC lattice is applied to the open cavity and unified using Boolean operations within the NX modeling environment.

By creating advanced lattice structures in NX, you can design with purpose and modernize manufacturing processes. Still not convinced? Stay tuned for the next article on Design for Purpose, where we will dive deeper into later stages of the end-to-end solution by applying lattice structural properties at the microscale to determine how and where designs are most likely to fail.

Sounds impressive, doesn’t it? You might think this is “too far-fetched,” but in the next article, we will introduce NX Multimechanics capabilities and explore workflows and benefits compared to traditional material testing options.

Source: Siemens

SDE Digital Technology Co., Ltd. (SDE TECH) was established in 2014. By 2018, we were honored to become a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in the Southeast Asia – Asia-Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter management solutions. Enterprises and customers who need to contact SDE TECH can find the information below:

Enterprises and customers who need to contact SDE TECH can find the information below:

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어