AXOSUITS USES SOLID EDGE TO BRING EXOSKELETONS FROM SCIENCE FICTION TO MEDICAL AND INDUSTRIAL MARKETS

Body augmentation and exoskeletons have long been a part of science fiction lore. Whether you look at the balance system of the power loader from Alien or a real-world athlete, robotic exoskeletons are at the center of engineers’ focus.

The current market for robotic exo-suits has more practical applications than sci-fi games and mech warriors. Andrew Kapy is the co-founder of Axosuits, a startup focused on human body augmentation, developing robots and exoskeletons with advanced projects aimed at medical rehabilitation units.

The Axosuits team saw an opportunity to improve patients’ lives with a better-designed, more affordable exoskeleton

“Exoskeletons have existed since the 1960s, with very little market penetration,” Kapy explains. “The main reasons were high costs and lack of interest from insurance companies. Our mission at Axosuits is to raise the standard of care by democratizing access to this technology.”

Building a Startup

Kapy’s background is in IT and engineering, and he has worked with multiple companies worldwide. “Ten years in this field, I held various management roles and worked with many multicultural teams,” he shares.

Axosuits was founded seven years ago with only a few ideas and sketches on a piece of paper.

Kapy says, “While exploring exoskeleton applications, we realized industrial use is a larger market, but the requirements vary greatly due to the many use cases.”

Although the industrial market seemed steady, a range of requirements pushed the Axosuits team to apply their ideas to medical purposes. Kapy notes that sourcing components is a major challenge when creating medical devices.

He explains: “There are limited suppliers and certified commercial off-the-shelf (COTS) components for medical use, which drives up medical device costs. It took us years and multiple iterations to find the right combination of affordable medical-grade components with the necessary reliability.

Compliance is also a major challenge. Interestingly, the lack of applied standards was another significant problem. There was also a mindset shift regarding compliance—not something most startup team members are excited about.”

Kapy’s team realized they needed not just a technically sound exoskeleton frame but also a more economical design

Designing the Mechanical Suit

Although exoskeleton systems have existed for decades as concept devices, they were impractical and too expensive for real-world applications, often serving only as secondary functions.

The Axosuits team began working on exoskeleton designs for medical purposes, targeting end-users who are patients with disabilities.

“We wanted to understand what patients and medical professionals look for in an exoskeleton,” he explains. “We also interviewed existing exoskeleton users to understand the limitations they experienced.”

In a medical environment with design challenges, Kapy faced patients with disabilities and complex emotions. The design process had to address not only functional issues in a specific market but also how users perceive medical devices.

After extensive interviews with various patients and potential end-users, the Axosuits team reviewed existing standards, draft standards, and regulatory requirements.

He says, “Only after these steps could the real engineering work begin. The process focuses on the final outcome, refining user requirements and work items.”

Using Solid Edge, the team could develop and refine their designs.

Axosuits interviewed medical exoskeleton users to pinpoint exactly where challenges exist

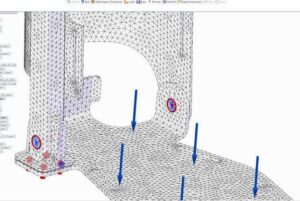

“We evaluated several solutions and found Solid Edge suited our needs,” Kapy explains. “We were looking for a mechanical design product with MCAD support, offering not only parametric design but also finite element analysis (FEA).”

The most critical feature for us, aside from parametric tools, was the FEA module. We saved significant development time by simulating motion, forces, and fatigue before actual integration. This shortened our development cycle and gave the company insights into better design practices.”

Leveraging Solid Edge for Startups

The Solid Edge for Startups program by Siemens provides qualified startups free access to the full suite for product development, including CAD, CAM, and CAE software.

Kapy explains that they contacted Solid Edge to speed up the process. “We requested a CAD license and received a call shortly after. Then, a local Siemens integrator visited to accelerate integration. The support provided reduced learning time and overall cost.”

Solid Edge offers complete solutions, from CAD and parametric modeling to simulation and manufacturing tools. Leveraging this toolkit gave Axosuits a head start in development.

“Solid Edge is a sophisticated tool, but the learning curve is manageable, and there’s a vast knowledge base,” Kapy says. “A key performance indicator we monitor is the time from first Solid Edge use to producing our first components.” According to Kapy, this timeline has shortened significantly, enabling rapid achievement of final results, which encouraged continued use of Solid Edge.

Axosuits is quickly moving toward large-scale production of medical exoskeletons. As production begins, they aim to optimize the manufacturing process, refining designs for manufacturability.

Axosuits used Solid Edge because they needed a tool with both parametric design and FEA simulation. Kapy’s team is refining the design to pursue opportunities in new markets, including industrial applications

With increased experience and understanding of market requirements and challenges, the Axosuits team plans to expand into new industrial sectors.

“We want to enter the construction sector, as it is an accident-prone environment lacking automation, ideal for researching our technology. To do this, we are actively seeking strategic partners to help scale as we move forward.”

The design team is also planning their next project, targeting more industrial applications.

Kapy says: “Now our mission is to bring industrial exoskeletons from design to physical product. We believe Solid Edge will give us the momentum we need to get the job done.”

Axosuits has carved a position in the market by reducing the prohibitive costs of exoskeleton technology. They can now modify designs to target other markets, one at a time.

Source: Siemens

SDE Technology Co., Ltd. (SDE TECH) was founded in 2014. By 2018, we proudly became a Smart Expert Partner – a leading Siemens Digital Industries Software partner in the ASEAN – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter management solutions.

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어