TEAMCENTER PARAMETER MANAGEMENT INTEGRATED WITH DIGITAL THREAD

Deliver Seamless Products Without Program Errors

Have you ever faced challenges in your development and business processes to build and deliver products that meet overall product objectives? Developing a new product or improving the performance of an existing product is a high-risk process with the potential for multiple programs to fail.

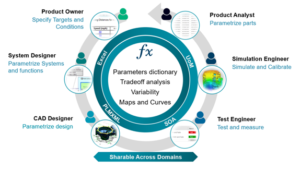

To ensure programs meet planned objectives, all stakeholders involved in the product development process must aim for a clear and measurable set of goals, verifiable at each development stage. See how Siemens can help you overcome this challenge with integrated parameter management on the Teamcenter platform.

Sew Digital Threads with Teamcenter Parameter Management

Integrated Parameter Management

What if you remove all the threads from your bag, sheets, and clothes? Clearly, they wouldn’t be useful without multiple threads stitched together. In the case of a thread connecting bags, sheets, and garments, Teamcenter Parameter Management helps you “stitch” a digital thread connecting all stakeholders.

- Capture product objectives and transmit them to primary and secondary systems

- Design primary and secondary systems to achieve corresponding sub-goals

- Verify that the resulting product meets overall product objectives

In the video below, see how digital thread parameter collaboration sets product goals, extracts physical and functional characteristics, and closes the loop with automatic verification of product objectives.

The scenario in the video illustrates how stakeholders in product development can weave all digital parameter threads together:

- At the customer’s request, Ben – the Product Owner – constantly requires the range of a full-load diesel pickup to be increased to 2500 km

- Ed, the Feature Owner, evaluates several options to meet the new product’s performance goals, such as improving fuel efficiency and/or increasing fuel tank capacity

- Before Linda, the Mechanical Designer, implements the proposed solution, Sam simulates the change through a virtual prototype to confirm it meets the continuous innovation range goal – test before you change!

- To close the loop, Ben reviews the new design solution and may reject it if it violates safety requirements

Break Down Product Goals with Digital Parameter Thread

The process of breaking down clear and measurable goals is critical in product development, especially for complex systems. You can align your product goals through the digital parameter thread using Teamcenter Parameter Management integrated with:

Requirement Management to define product objectives

System Modeling Workbench and NX to capture functional and physical product characteristics

Verification Request and Teamcenter for Simulation for simulation to automatically verify and validate designs.

By enabling product development stakeholders to weave digital parameter threads together, you can shorten product design cycle times, avoid late design rework, and increase the likelihood that costly physical prototypes come closer to achieving product objectives and quality.

Source: Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was established in 2014. By 2018, we were honored to become a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in the Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

For businesses and customers, please contact SDE TECH using the information below:

For businesses and customers, please contact SDE TECH using the information below:

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어