4 NVH ENGINEERING TRENDS YOU SHOULD NOT MISS [PART 1]

What is the role of Noise, Vibration, and Harshness (NVH) engineering in today’s automotive development cycle? How can it be rigorously aligned with the major trends shaping the automotive industry? Join the discussion with Steven Dom on the current trends in NVH engineering.

After addressing NVH engineering, first in the context of vehicle electrification and then optimizing conventional powertrains, we take a broader look at full-vehicle NVH performance trends.

Indeed, it’s time to sit down with Steven Dom for a friendly conversation about trends, industry outlook, and more. In this interview, Steven highlights four global trends currently impacting this field.

Grab a cup of coffee or a glass of wine, and join the conversation with us.

Trend 1 – Modern NVH Engineering Focuses on Process Efficiency

Steven Dom begins by discussing what he knows best: the automotive development process and NVH engineering’s role within it.

High-skilled vs. low-skilled engineers

Considering his expertise, he offers almost a justification: NVH engineers often have a “bad” reputation. They are troubleshooters, sometimes even seen as troublemakers. Their work often occurs late in the automotive development cycle, leading to costly redesigns or unnecessary minor fixes.

As a result, many NVH engineers now focus on addressing potential issues earlier in the design process, enhancing their reputation.

There are multiple ways for NVH engineers to integrate their expertise more effectively and earlier.

Start small to achieve big results

Sometimes it begins with a series of small process improvements to streamline NVH testing. Engineers may propose standardized procedures, use pre-defined best-in-class prototypes, or leverage multiple channels for faster, more efficient checks.

While these small steps do not eliminate the need for final NVH validation, they ensure the process is as smooth and efficient as possible.

Beyond minor improvements, companies are making more fundamental changes. Ford Motor Company, for example, uses a consolidated testing approach where testing principles are applied together to improve overall efficiency.

“The temptation to become a technical specialist can backfire. Vehicles are complex systems exposed to various environmental loads. Noise, vibration, thermal effects, electromagnetic interference, and other characteristics interact. Companies recognize that a rigorous cross-disciplinary approach to driving, handling, and comfort issues is essential,” Dom explains.

A new generation of “super” engineers

It’s no longer about testing everything separately. Now it’s “goodbye bookish NVH engineer, hello multi-functional super engineer!” They are no longer labeled as “test” or “simulation” engineers. As NVH becomes more integral to the vehicle development cycle, companies integrate processes to blur the line between testing and simulation.

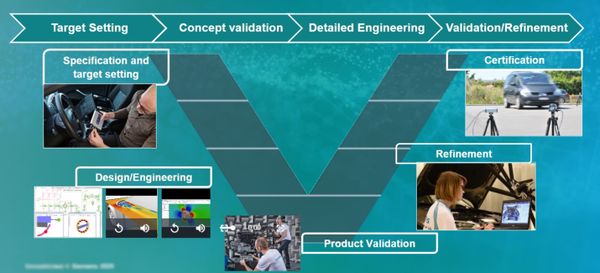

NVH engineering has also become part of the full Product Lifecycle Management (PLM) process. Dom adds: “Companies are now developing NVH engineering effectively within the development cycle, a reality only recently achievable after decades of discussion.”

Modern NVH engineering blurs the boundaries between disciplines and enables earlier action in the automotive development cycle

“The temptation to become a technical specialist can backfire. Companies recognize that a rigorous cross-disciplinary approach to driving, handling, and comfort issues is essential.”

Trend 2 – Streamlining as a New Approach to NVH Engineering

According to Dom, the second trend impacts NVH engineering indirectly. In recent years, OEMs have identified the need to streamline product and vehicle development. How does this affect NVH engineering?

The explosion of vehicle variants

Streamlining? Over the decades, the number of vehicle models in local markets has exploded. Take Mercedes-Benz, for example: in the 1980s, the company produced only a few luxury sedans – C-class, S-class, E-class (and G-class, a distinct category). Then came the A-class in 1997 and the B-class in 2005, continuing the trend over the next decade.

Nearly all automakers went through this phase of market complexity, offering vehicles for every consumer segment – from single-parent families to elderly couples.

Vehicles for virtually every consumer segment, from young families to seniors.

To keep up, OEMs adopted platform strategies. Instead of developing 25 completely different models, they create variants – coupés, hatchbacks, SUVs – based on 4-5 common platforms, shared across brands or even companies.

Beyond platform strategies

However, automakers realized even platform strategies were insufficient to keep pace with innovation and market competition. Instead of flooding the market with new models, some companies streamlined their offerings. Mercedes, for instance, phased out the A-class to focus on their flagship luxury sedans.

Now, modular approaches replace platform strategies. Modules act as building blocks reused across different vehicle types. Different vehicle models share suspension components, radiators, or steering systems. Cars are assembled from individual parts like Lego blocks.

Volkswagen uses this approach with the Modular Transverse Toolkit (MQB), underpinning models from the small Polo to the large Atlas SUV. All MQB models have a front-mounted transverse engine. MQB provides space efficiency while allowing freedom to choose powertrains, from gasoline, diesel, CNG to electric and plug-in hybrids.

MQB method combines fixed and variable components

A modular approach significantly reduces costs by allowing mass production of subsystems.

What it means for NVH engineers

Perhaps they now get to play with Legos?

Engineers built a full-size Bugatti Chiron from Lego blocks – and it can actually run!

More seriously, you don’t need to be an AFOL (Adult Fan of Lego) to master modular NVH engineering. Innovations like virtual prototyping enable vehicle models built from existing and new subsystems to predict NVH behavior earlier in the design cycle.

Dom explains: “Component-based transmission path analysis predicts NVH behavior at the subsystem level. It allows modeling parts like power steering, HVAC pumps, or wiper assemblies independently from the receiver structure. Engineers can then predict noise and vibration when combined with other receivers.”

This approach enables suppliers to specify parts independently from the full vehicle receiver. It’s based on blocked forces concepts and joint structure modeling, predicting how a component interacts with the vehicle. Dom adds: “Engineers can safely forecast full-vehicle NVH performance before production. It also allows OEMs to set clearer targets and collaborate more effectively with suppliers.”

This method prevents late, costly fixes and supports building knowledge for future generations.

For more, see the webinar: Component-based TPA – Your future-proof strategy to drive NVH vehicle development.

Source: Siemens

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어