MULTI AXIS DEBURRING FEATURE IN NX CAM

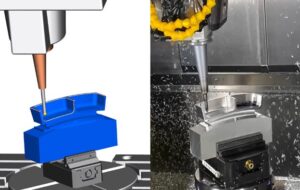

In the latest version of NX CAM (June 2021), a new sub-feature – Multi Axis Deburring – was introduced to help reduce programming time, create smart, collision-free cutting operations, and output optimized toolpaths for high-efficiency machining.

The Multi Axis Deburring feature allows you to create 3-, 4-, and 5-axis edge deburring operations whether chamfers and fillets are modeled or not. NX CAM automatically recognizes edges of parts with any level of complexity and then generates multi-axis operations to machine the specified chamfer dimensions.

Multi Axis Deburring in Action

Multi Axis Deburring supports faster detailed programming by automatically detecting edges and tilted tool axes based on the user’s intent to create safe and efficient toolpaths. To validate generated toolpaths, you can run G-code simulations before sending the program to the CNC machine. Depending on the part geometry, you can quickly generate various multi-axis operations such as 3+2 axis machining, 4-axis, and full 5-axis machining.

Multi Axis Deburring also supports the use of different cutting tools, including ball, spherical, conical, and lollipop tools. Advanced controls allow you to define cutting patterns, tool axes, and tool movements, ensuring smooth and optimized machining operations.

Source: Siemens

SDE Digital Technology Co., Ltd. (SDE TECH) was established in 2014. By 2018, we were honored to become a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in the Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions. Businesses and customers can contact SDE TECH as follows:

Businesses and customers can contact SDE TECH as follows:

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어