TEAMCENTER X: SIMPLIFYING BOM MANAGEMENT WITH CLOUD-BASED SAAS SOLUTION – PART 1

1. THE ROLE OF BOM IN PRODUCT DEVELOPMENT

The Bill of Materials (BOM) is a critical component of product development. Once engineering develops it, various departments in the company use it to move from design to production to maintenance. Therefore, the BOM is a key element for many stakeholders, both inside and outside the company, including departments such as manufacturing, procurement, sales, accounting, and service.

Each department has the function of adjusting and modifying the BOM for its own purposes.

- Engineering: relies on the BOM to track modifications and changes, meet cost objectives, and comply with product performance, capability, and safety requirements.

- Manufacturing: uses the BOM to plan production processes and assembly operations.

- Procurement: plans for product components.

- Service: refers to the BOM for planning service operations and providing spare parts.

- Executive management: relies on the BOM to assess risks and develop risk management strategies.

This article focuses on the challenges of BOM management and how cloud-based Software as a Service (SaaS) solutions can help businesses overcome these challenges.

The BOM is a critical factor distributed throughout product development and used by multiple departments

2. CHALLENGES IN BOM DEVELOPMENT

The BOM is a key element in product development. Product development teams need to create, manage, and refine the BOM throughout the design cycle. However, today’s BOM development faces several challenges that companies are trying to overcome.

The growing demand for smart products means companies face increasing complexity, requirements, and product diversity. Continuous cost pressure also forces companies to standardize components. This makes the BOM more complex and significantly complicates BOM management. Companies are seeking better ways to develop and manage their BOMs.

Because the BOM is crucial to the entire product development process, any changes in creation or management must be at least as efficient and cost-effective as traditional methods. Furthermore, many companies are seeking better solutions to address challenges such as the COVID-19 pandemic. Modern Product Lifecycle Management (PLM) solutions provide significant advances through superior workflow processes.

Creating and managing a BOM is a collaborative process

3. SYNCHRONIZING A BOM FROM MULTIPLE DATA SOURCES

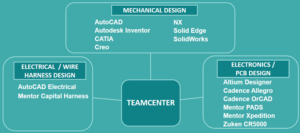

Today’s smart, connected products include mechanical, electrical, electronics, and software components. Naturally, the BOM must reflect this and incorporate data from various stakeholders and software. Different departments rely on the BOM to make decisions. Therefore, the BOM must link to CAD design data and supplier databases to ensure information is accurate and up-to-date.

Maintaining and updating all this data is a challenge. Those responsible for the BOM must ensure it is updated whenever CAD models change. Traditionally, companies used emails or spreadsheets to update this information. However, manually updating these sources can be time-consuming and error-prone, causing stakeholders to work with outdated versions.

Fortunately, PLM software addresses these issues. BOMs can be automatically generated based on existing models or whenever CAD models are modified. This solution provides an automated way to synchronize multiple internal and external data sources necessary to complete the BOM.

The BOM can include mechanical, electrical, electronics, and software data and will update automatically when data changes

Source: SDE TECH

SDE TECHNOLOGY CO., LTD (SDE TECH) was established in 2014. By 2018, we became a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어