WHAT’S NEW IN SOLID EDGE 2022 SIMULATION

Faster Simulation

Simulation-driven design allows designers to receive immediate feedback on design performance by embedding simulation within the computer-aided design (CAD) environment and the designer’s workflow.

As part of the Solid Edge 2022 release, Solid Edge Simulation accelerates simulation studies with automated design performance validation workflows. Solid Edge continues to provide engineers with powerful simulation tools to validate digital designs and create better products in less time by preloading the simulation process.

New automatic meshing workflows provide high-quality meshes with minimal effort by controlling mesh quality without manual parameters. Simulation meshes can be generated directly on the existing geometry, making Solid Edge stand out. No reverse engineering or other complex workflows are required.

The Body Mesh option, a new Siemens meshing technology, simplifies and improves tetrahedral meshing for complex parts with intricate bodies, automatically removing small edges and surfaces. The mesh can be validated using results from 3D scans or general studies, delivering reliable simulation outcomes.

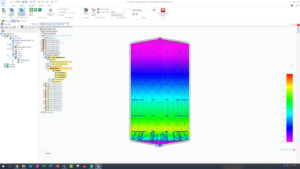

Solid Edge Simulation can calculate Hydrostatic Pressure loads in a linear static or combined study. This can be used to determine maximum and minimum pressures generated by a fluid in equilibrium, addressing customer demands for high performance and efficiency in hydraulic systems.

Hydrostatic Pressure Analysis Results

Simulation display performance is now up to 10 times faster than before, optimizing result data loading times and making Solid Edge Simulation faster than ever. Display performance improvements include mesh loading and decomposition efficiency, optimized result data loading times, optimized display of constraint, load, and connection symbols, and mesh visualization performance.

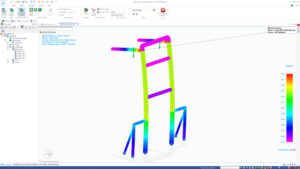

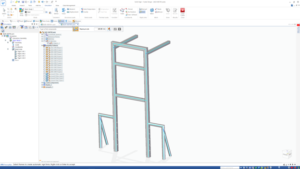

We have also added the ability to view Beam von-Mises stress charts for frame models. The safety factor chart has been enhanced and now based on von-Mises stress, producing much more accurate results than the previously used maximum composite stress. Instead of only adding stress levels, it evaluates the complex stress factor for safety using formulas.

Beam Von-Mises Stress

The Beam model has been improved with automatic beam creation for better model definition and supports manual rigid link specification, allowing the maximum rigid link length to be set.

The new automatic link creation now considers all cases requiring rigid links and only creates necessary links for the study. We can adjust the connector option to specify the maximum rigid link length for automatic creation, or use the Auto Link command for much faster model setup. Digitally connected elements prevent unnecessary rigid elements at corners.

Rigid Links

Source: Siemens

SDE TECHNOLOGY CO., LTD (SDE TECH) was established in 2014. By 2018, we became a Smart Expert Partner – a leading partner of Siemens Digital Industries Software in the Southeast Asia – Pacific region for Siemens NX (Unigraphics NX), Simcenter, Solid Edge, Tecnomatix, and Teamcenter solutions.

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어