SERVICE

SDE TECH provides services as well as solutions about CAD/CAM with good price on market.

What is Post-Processor?

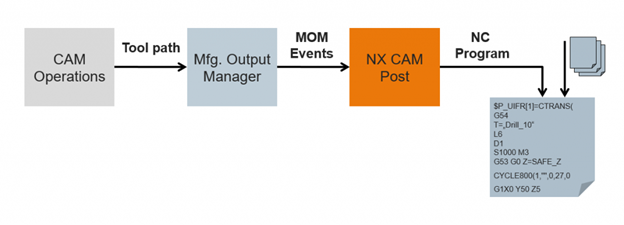

To create an NC program from a CAD model, we need to use machining software solutions to create toolpaths. However, CNC machines cannot read toolpaths directly on CAM software (apt, cls, …), but they need to be converted to a command format that matches the control system that the CNC is using.

Post-processor can be interpreted as a program that converts toolpath data into a command to control the CNC machine. In addition, users can add many other control features to post-processors that automate many CNC operations.

Based on Siemens NX platform, we provide post-processor construction services for all CNC series from 3-axis to 5-axis and milling centers. Combined with the construction of virtual machine models, configuration of the control system on NX software helps ensure the highest accuracy and safety in programming and controlling CNC machines.

Finished projects

5-axis CNC Machining Center DMU 50 (XYZBC)

- Controller: Sinumerik 840D

- Supported Function: Cycle800, AROT

- Supported Function: Traori

- NC Simulation

4-axis CNC Machining Center CRC120 (YZC+A)

- Controller: Fanuc16M

- Specialize for car shell mold machining with 3-axis

- Simultaneously YZC and combination of A-axis rotation

- NC Simulation

5-axis CNC laser machine Shibuya Silas (XYZBC)

- Controller: Fanuc18i

- 5-axis laser cutting machine for cutting pipe and sheet profiles

- Automatic limitation 90-degree rotation angle, cutting profile geometry control

5-axis CNC Machining Center Yasda 640V (XYZBC)

- Controller: Fanuc30i

- Supported Function: RTCP G43.4

- Support for 5 axis machining (3+2) with G68.2

- Intelligent angle reset allows unlimited running of C-axis

4-axis CNC 4 Makino (XYZA)

- Software: SolidCAM

- HDK: Fanuc11M

- Support original shift function automatically

- Support functions optimized speed when running 4 simultaneous axis

4-axis CNC 4 Mazak HCN 5000 (XYZB)

- Software: SolidCAM

- HDK: Mazak SmoothG

- Support original shift function automatically

- Support functions optimized speed when running 4 simultaneous axis

Shop Floor Documents Standardization in NX software

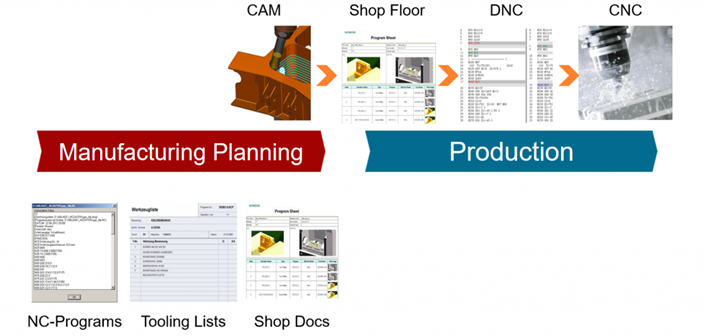

In CNC machining, technical documents have a very important role to help ensure a close link between CAD / CAM programming department and production department.

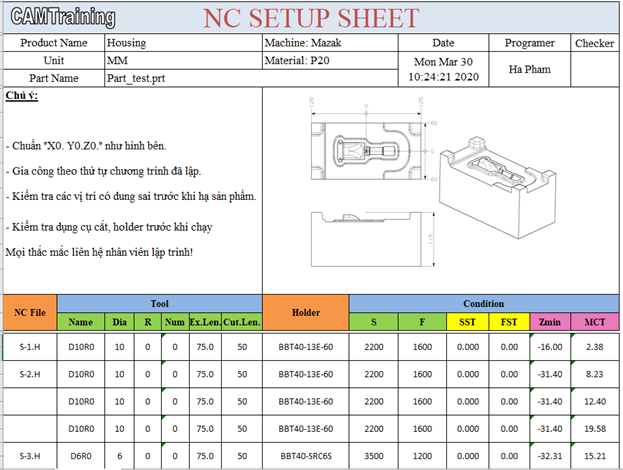

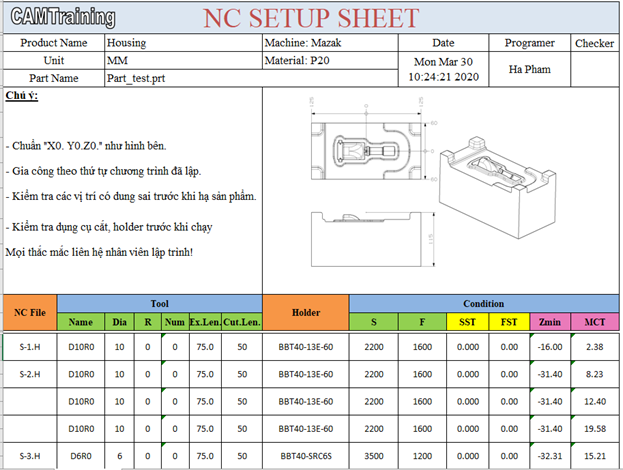

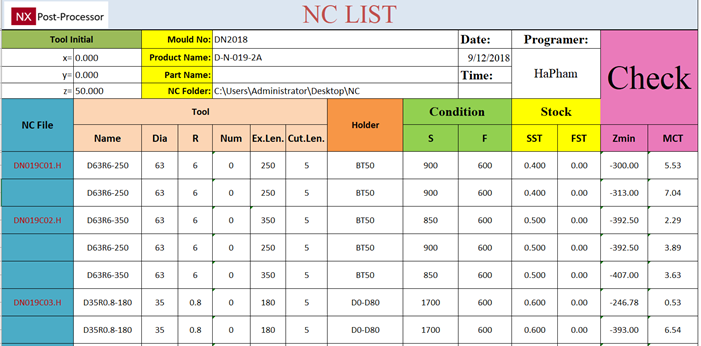

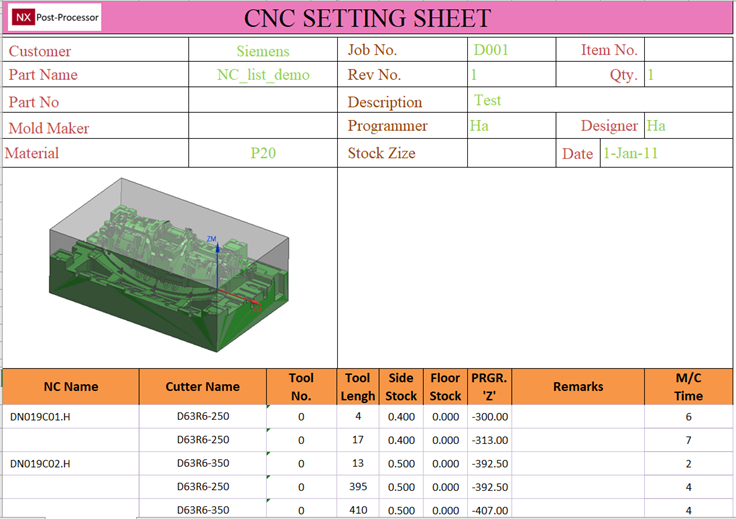

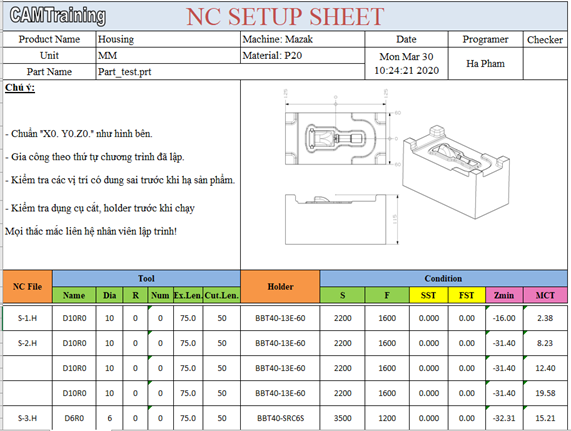

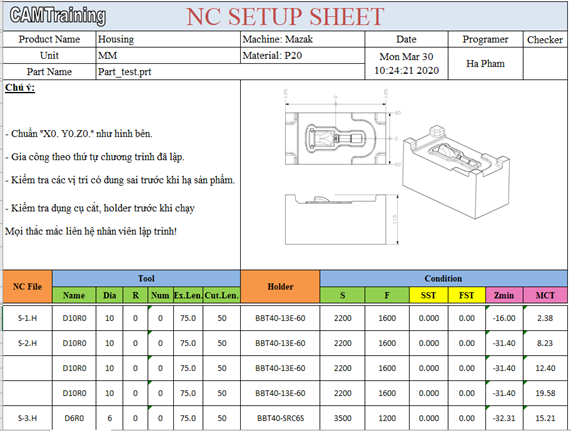

In order for all information to be accurate and up to date, we develop document standards with all the information needed for CNC machining. Parameters are created automatically from programming data on NX software. Documents exported as excel or pdf files can contain installation diagrams, detailed drawings, cutting tools, …

Features

Production documentation contains important information during the setup process at the machining workshop. Documents created completely automatically on NX programming files and directly linked with post-processors ensure all parameters are accurate and secure. Documents will include:

- Detailed drawings;

- NC program (name & folder);

- Tool parameter (diameter, R, tool length, number);

- Cutting parameter (S, F, Zmin, Stock, Machining time…).

Block "3768" not found

Tiếng Việt

Tiếng Việt 日本語

日本語 한국어

한국어